Heavy Equipment Manufacturers

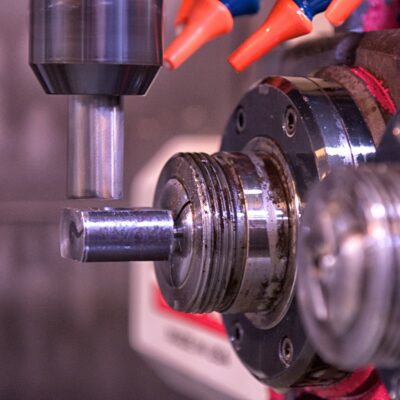

M&M Automatic Products builds a range of components for heavy equipment manufacturers, including manufacturers working with agricultural equipment, construction, oil and gas mining, aerospace, heavy trucks and many more. We understand how important it is that these components are built to last and endure tough conditions. With the ability to work with many different high-quality, durable metal alloys and fabricate components of many varying sizes and shapes, we are able to build heavy equipment components that withstand rigorous use. From gears and housings to assemblies, shafts, valves, and more, we work with great accuracy and care to meet the needs of your machines and provide components that are both sturdy and precise. We specialize in short runs and small lot sizes, typically between 50 and 100,000 pieces. With a variety of CNC turning and milling machines, screw machines, and more, we have the capabilities to manufacture nearly any part in the heavy equipment space.

We are:

- ISO 9001:2015 certified

- Expert machinists with 30 years of experience

- Specializing in runs between 50 and 100,000 pieces

- Experts in design, machining and finishing services

Our CNC Machines:

- Haas VF-2SS machining centers with 4th axis capabilities ( max material size of 24L x 13W x10H )

- Haas VF-2 machining centers with 5th axis capabilities ( max material size of 24L x 13W x10H )

- Haas TM-1 Tool Room Mill with 3 axis capabilities ( max material size of 24L x 8W x 6H )

- Haas ST-10 Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 1-3/4”)

- Mori Seiki SL204SMC Main/Sub Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 2-9/16”)

- Hardinge Talent 51 Turn/Mill Center with Bar Feeder (Max Barfed Bar Diameter @ 2″)

Our Screw Machines

- 9/16″ RA6 Acme Gridley

- 1″ RA6 Acme Gridley

- 1-1/4″ RA6 Acme Gridley

- 2-5/8″ RA6 Acme Gridley

- 1-5/8” 6-spindle Greenlee

- 2” 6-spindle Greenlee

Get a Quote for Your Heavy Equipment Components Project

Do you have questions about CNC machining for your heavy equipment components? Let us help.

Durable and Precise

Heavy machinery components must be made to last. We work with some of the toughest metals, including carbon alloys, multiple stainless steel alloys, nickel alloys, and more, to build components that withstand long hours under extreme conditions. Our CNC milling, turning and screw machines can accommodate components with dimensions up to 14.00” inches in diameter 12” inches long, allowing us to build components for some of the most demanding industries. With tolerances ranging from ± .0002 inches for our CNC machines and ± .002 inches for our automatic screw machine, we can build large, durable components that are also made with precision.

Whether you need an emergency part replacement to get your equipment up and running again or you are an OEM or replacement parts manufacturer in need of supplementary manufacturing, we can help. In addition to a range of machining, milling, and turning services, we also offer anodizing, plating, grinding, finishing and design assistance to ensure your parts are constructed accurately and economically.

We work with the following materials:

- Carbon alloys

- Stainless steel

- High nickel alloys

- Titanium alloys

- Aluminum

- Brass

- Plastics

Exceptional Service and Quick Turnaround

Whether you are in need of standardized, relatively simple components for heavy equipment or a unique and highly specialized component, we can help. Our engineers and designers will work with you to design the best manufacturing method and ensure that the finished product meets your standards and expectations. With over 30 years of experience, many of our machinists have worked with the full range of products and components. We can take your design and build a tough, long-lasting component that will continue to perform well into the future.

In addition to high-quality manufacturing, we also understand the need for quick turnaround. If you are in a tight spot and you need your heavy equipment components machined quickly, we can help. Tell us about your schedule and timeline, and we’ll do everything possible to meet your needs.

In addition to CNC machining services, we also offer the following services to help complete your project smoothly from start to finish:

- CAD/CAM design assistance

- Anodizing

- Plating

- Grinding

- Finishing

- Assembly

- Warehousing

- Packaging

- Just-in-time delivery