Screw Machine & CNC Machining Capabilities

High precision CNC & screw machine shop

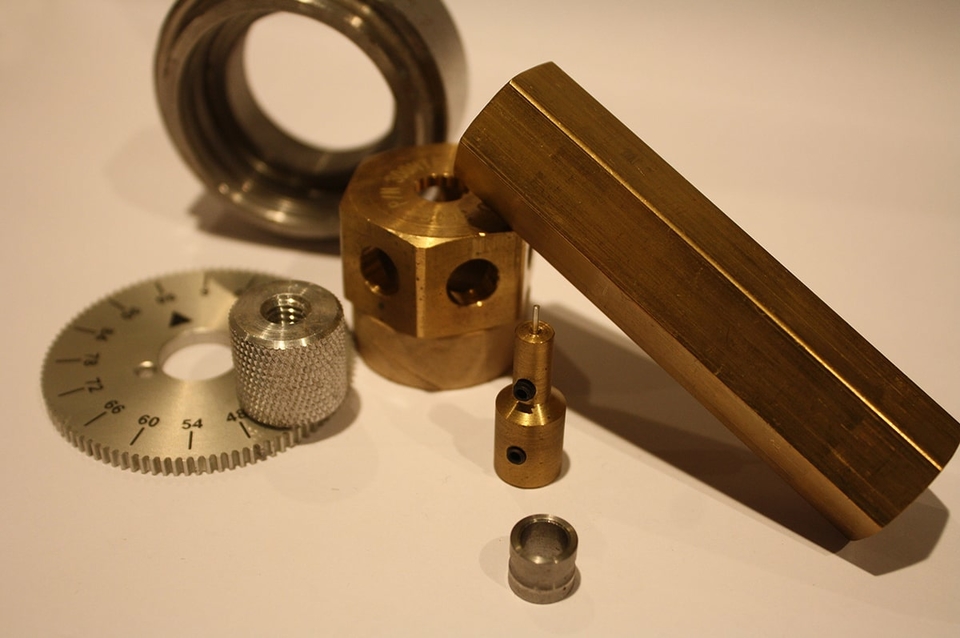

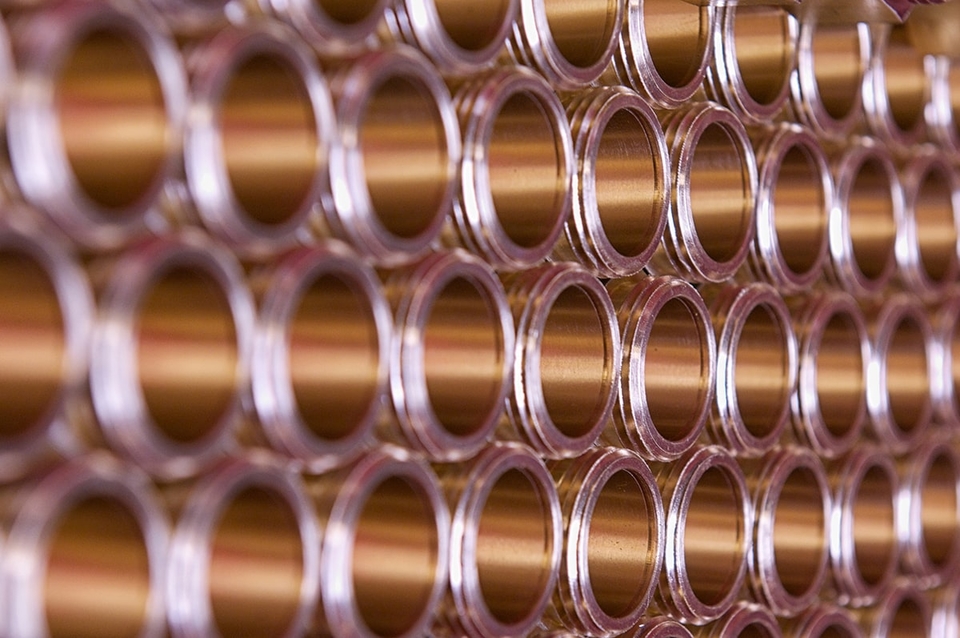

Producing your parts quickly, cost-effectively, and with the quality you expect takes high-quality, carefully maintained equipment run by experienced machinists. From our CNC turning centers and CNC mills to our wide variety of screw machines, we have the equipment it takes to deliver your parts on time and to print. Plus, we can run a variety of materials, including carbon alloys, aluminum, brass, stainless steel, titanium alloys, high nickel alloys and plastics.

CNC Milling:

- Haas VF-2SS machining centers with 4th axis capabilities ( max material size of 24L x 13W x10H )

- Haas VF-2 machining centers with 5th axis capabilities ( max material size of 24L x 13W x10H )

- Haas TM-1 Tool Room Mill with 3 axis capabilities ( max material size of 24L x 8W x 6H )

CNC Turning:

- Haas ST-10 Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 1-3/4”)

- Mori Seiki SL204SMC Main/Sub Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 2-9/16”)

- Hardinge Talent 51 Turn/Mill Center with Bar Feeder (Max Barfed Diameter @ 2″)

Automatic Screw Machine:

- 9/16” RA6 Acme Gridley’s

- 1” RA6 Acme Gridley’s

- 1-1/4” RA6 Acme Gridley’s

- 2-5/8” RA6 Acme Gridley’s

- 2” 6-spindle Greenlee’s

Miscellaneous Equipment:

- Various secondary operation equipment capabilities

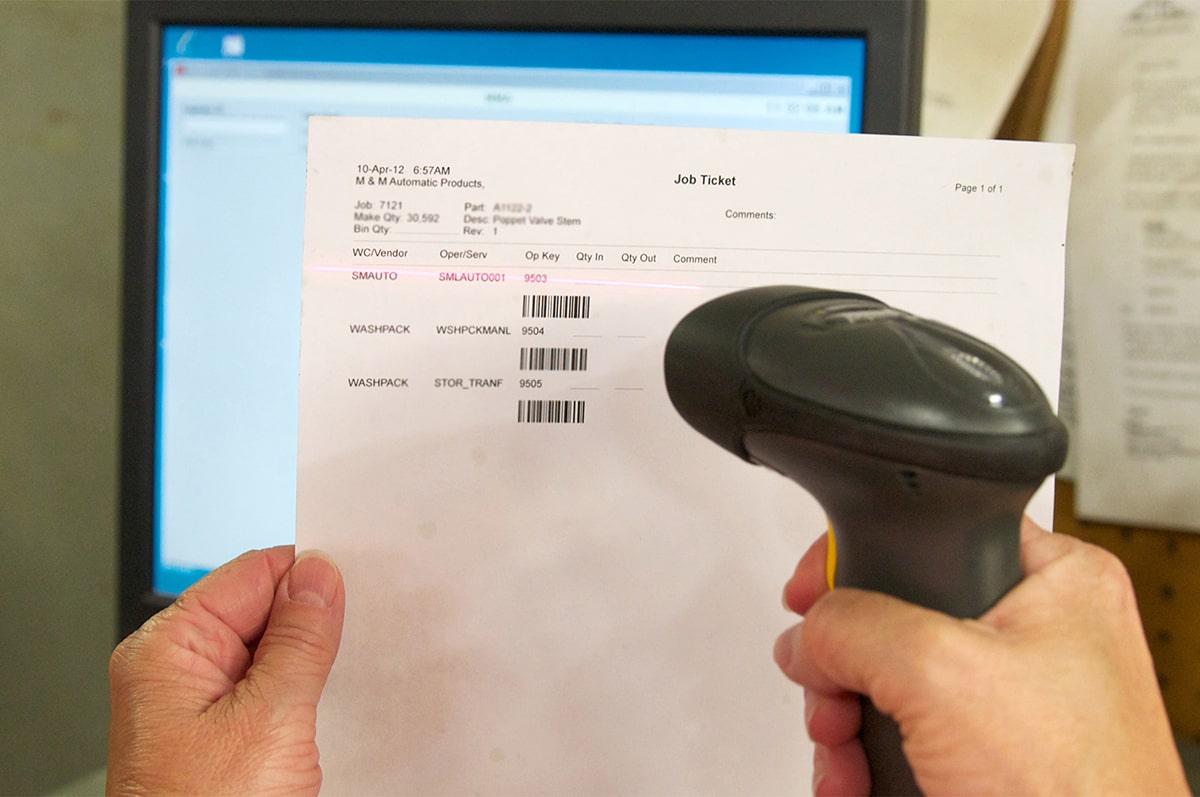

Quoting

Machining

Finishing

Assembly

Logistics

Get Affordable, USA-Made Precision Machined Parts Fast!

From prototype to product, our world-class screw machine shop and expert machinists can provide custom screw manufactured parts to print, within budget and in a quick time frame to meet the demands of your project or industry.