CNC Milling

Meeting Your CNC Milling Needs From Prototype to Production

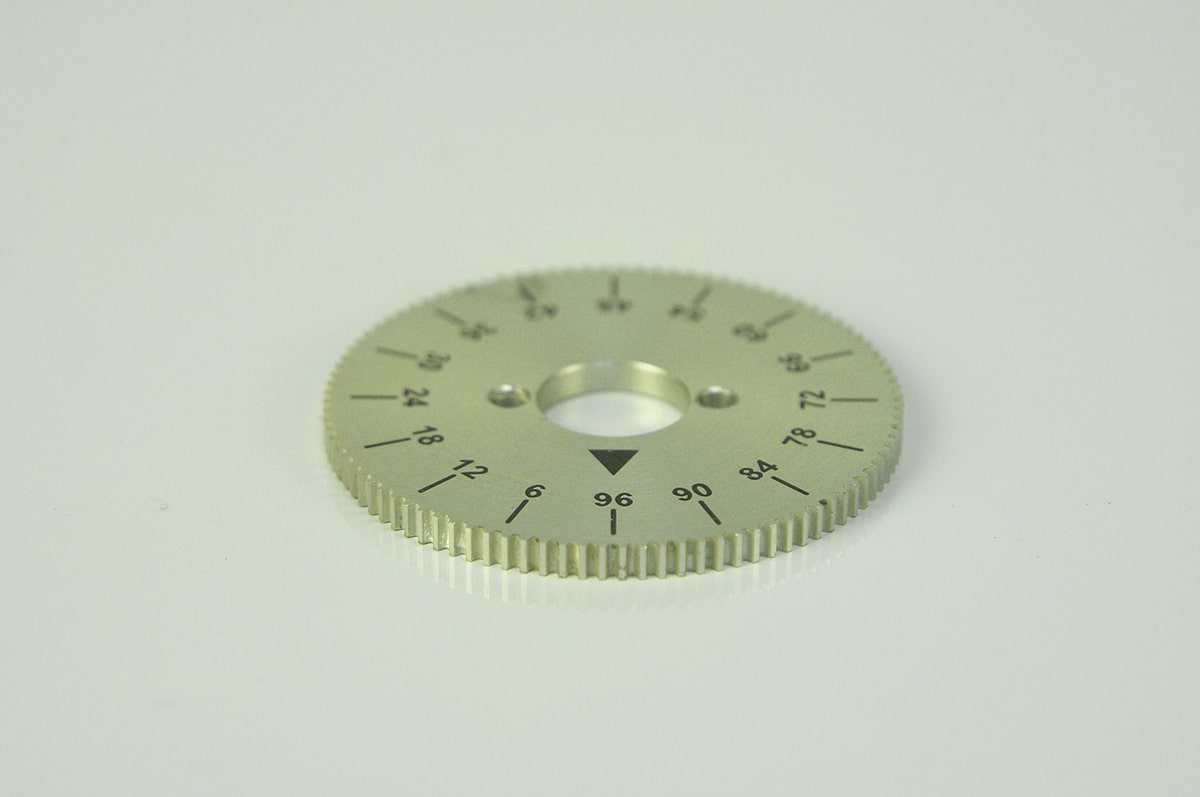

For over 30 years, M&M Automatic Products has been a leading provider of CNC Milling services and parts for companies around the globe. Whether you need a short run of complex parts, require precision finishing services, or simply need the ability to run a variety of materials, our CNC milling equipment can meet your machining needs from prototype to production. Our experienced machinists are equipped to quickly and accurately set up even your most complex jobs and deliver them on time, to print, with the quality you expect.

CNC Milling Services & Capabilities

Our team of CNC milling machinists specialize in short runs and small lot sizes, and our typical runs range is from 50 to 100,000 pieces. Utilizing some of the most advanced CAD/CAM software available, we are able to take your ideas from concept to finished part. Our versatile CNC milling machines are capable of running a variety of materials, including carbon alloys, aluminum, brass, copper alloys, stainless steel, high nickel alloys, titanium alloys and plastics. We can also help you choose the best material for your application and help you determine the best way to reduce your part’s cost without any reduction in quality or performance.

Our equipment is designed to hold production tolerances of plus/minus .0005” on most dimensions:

- Haas VF-2SS machining centers with 4th axis capabilities ( max material size of 24L x 13W x10H )

- Haas VF-2 machining centers with 5th axis capabilities ( max material size of 24L x 13W x10H )

- Haas TM-1 Tool Room Mill with 3 axis capabilities ( max material size of 24L x 8W x 6H )

How it Works

When you contact M&M Automatic Products requesting a quote, we will set up a consultation to review your product needs and design a plan based on your timeframe and budget. We can even help you design your parts and determine what would be the best raw materials to use to produce them. Our CNC milling machinists will then manufacture your parts and will have them shipped and into your hands on-time and on-schedule. We’re even capable of producing your parts on an expedited timeframe if needed!

Why M&M Automatic Products’ CNC Milling Services?

Our team of expert machinists have been providing CNC milling services for over 30 years and is focused on providing you the high-quality parts within a timeframe and budget that fits your project needs. We are ISO 9001 certified and continually maintain a rigorous quality assurance program as well as machinists training programs to ensure that our products exceed our customer’s expectations. Whether you need more information on our CNC milling capabilities, need a quote or want to check the status of your order, our friendly, knowledgeable staff are always happy and available to answer your call.

What is CNC Milling?

Milling has been used for centuries to craft and shape tools and components. Over the years, milling processes have changed and become more advanced. Computer Numerical Control or CNC milling uses a computer control system to create precise shapes and make exact cuts. Once a CNC milling machine is properly set up, a digital plan informs the machine how to cut and shape a piece of stock, usually a piece of metal.

What is the difference between CNC Turning and CNC Milling?

CNC turning and CNC milling are similar processes and can easily be confused. Both of these are subtractive processes that remove material from a piece of stock to create a shape, as opposed to an additive process, like 3D printing, which adds material as it creates a shape. The main difference between CNC turning and CNC milling is the specific way the shape is created. In CNC turning, the workpiece rotates against cutting tools to make a shape. In CNC milling, cutting tools rotate around the workpiece.

What materials do CNC milling machines use?

CNC milling machines are capable of working with many different types of materials. Metal alloys are the most common, including aluminum, brass, copper alloys, stainless steel, high nickel alloys, titanium alloys and carbon alloys. Different types of plastic may also be used. The material must be hard enough to withstand the force of the milling machine, and also flexible enough to withstand subtractive manufacturing without cracking or shattering.

What are CNC milling machines used for?

While CNC turning is ideal for creating conical or cylindrical pieces, CNC milling is more versatile and can make flat surfaces, deeper holes and more unique shapes. CNC milling is generally considered to be a more precise process and can perform a wider variety of cuts. The mills can drill cuts with some limits on depth and width. Milling machines can also cut grooves, pockets, planes, edges and even engraving.

How close are your CNC milling machine tolerances?

Our CNC milling machines operate at a tolerance of plus/minus .0002”

What is a typical run for a CNC milling machine?

CNC milling is generally best for prototypes and short runs between 10 and 1,000 pieces.

Latest Blog Posts View All ›

Get Affordable, USA-Made Precision Machined Parts Fast!

From prototype to product, our world-class screw machine shop and expert machinists can provide custom screw manufactured parts to print, within budget and in a quick time frame to meet the demands of your project or industry.